Monitoring and remote control

Continuous analysis allows to intervene promptly on the causes of alarm, while a precise activities of ordinary maintenance allows to avoid most of the possible problems.

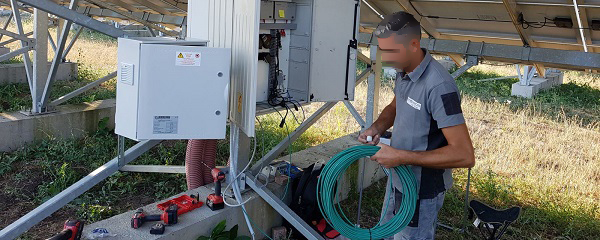

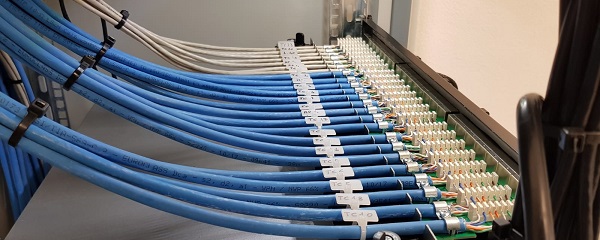

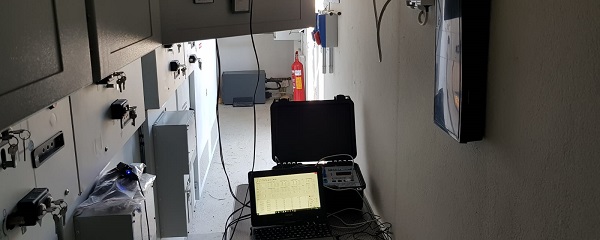

The Telecontrol Service, edited by specialized Erross technicians, has for aim the control of the functionality, productivity and efficiency of the system. Depending on customer needs, we can implement one of the most advanced systems on the market nowadays, providing cost-effective hardware and software to manage all the parameters needed for efficient and reliable control of the entire plant. If the monitoring system is already present, we are studying how to adapt it to make it efficient and going very often to cut out the yearly running costs of technology that has become obsolete.

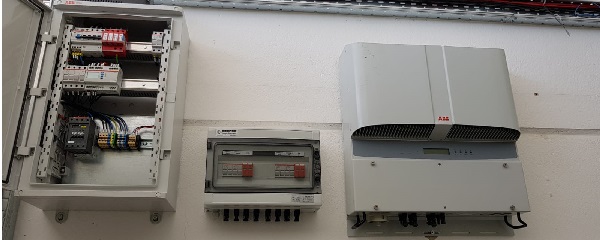

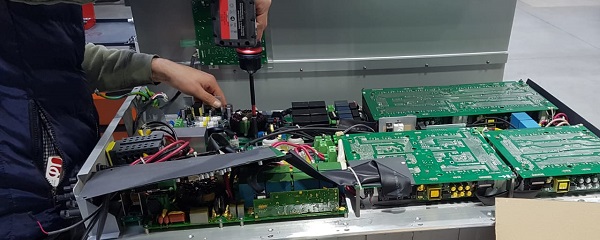

Thanks to the remote control system, each component of the system is monitored: panels, strings, square (or parallel control), switches, inverters, protective equipment, environmental variables, UPS, etc...

In addition to allowing continuous analysis, the Remote Service also allows you to detect and promptly handle any faults that may occur on the system, thus guaranteeing to minimize production losses.

Additional abnormalities can be detected by comparing the data of productivity and efficiency of the photovoltaic system in question with the information collected on over 300 photovoltaic plants (over 20 MW in Northern Italy), both of Erross Customers that of third.

With Erross S.r.l. Telemanagement is possible:

- constantly monitor the actual production compared to the expected (design data), then analyzing the performance of the system, recording the production data, radiation, meteorological parameters, calculation of availability and performance ratio;

- promptly detect the presence of any anomalies (out of service, lower production, forms dirty, overtemperatures, shading, etc...) in order to limit the loss of production by a decisive intervention by the Erross personnel;

- deliver to Customer the Monthly Report indicating, in addition to the comparison of the values recorded between actual production and estimated production (performance of the system), the alarm history and decisive action during the month.