Are you sure it's working correctly? Your PV power plant is like your car, if you treat it well and you do all the inspections it will last for a long time, if you do not maintenance it will not last long and in case of breakdown, recovery will be costly and invasive. Typically a PV power plant needs routine maintenance at least once a year.

This intervention is generally carried out in the spring, for a tune-up of the plant in conjunction with the beginning of maximum production period of the year.

The owners of large PV power plants subscribe with us ordinary and extraordinary maintenance contracts before the entry into operation. This is because even a small problem can stop the production of the entire plant and it is important that the same is always kept in its condition of maximum efficiency to meet the initial economic plan and make the highest possible gain.

Even small PV power plants (<20 kWp), installed on the roof to respond to the family's energy needs, they require regular maintenance and control of production data for the same reasons. Very often it happens that the installer of the PV plant does not inform the customer that this must be maintained at regular intervals and makes him believe that once accommodated the modules on the roof they will function without problems for 20 years.

This our promotion campaign is aimed at owners of small plants, that sooner or later will have to deal with the decrease in production due to possible defects or simple dirt accumulated over time on the modules (which in many cases cannnot be removed from rainwater). Thanks to the professionalism of our staff and our equipment we can make each of our maintenance activities in a short time and this allows us to offer very competitive prices. You will get the maximum benefit by requiring all options of the PV power plant check-up because this allows us to offer an additional discount of 20% on our price list.

The check-up consists of three activities which performed all together guarantee the return of the PV plant to the state of maximum possible performance:

- Instrumental control;

- Thermography;

- Modules dry.

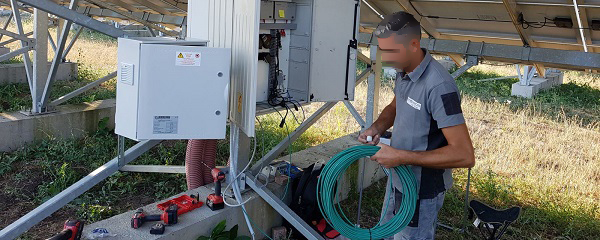

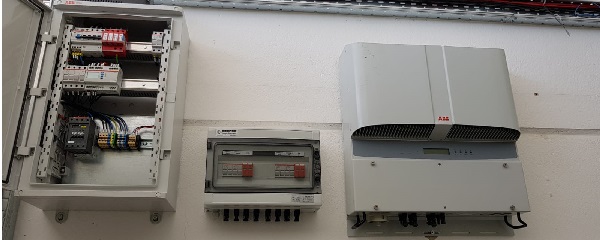

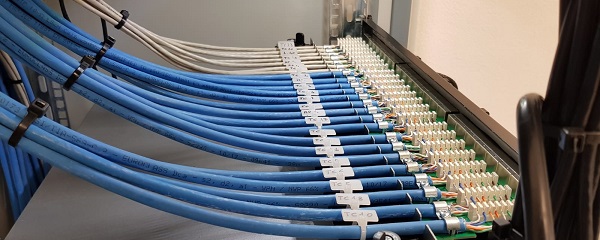

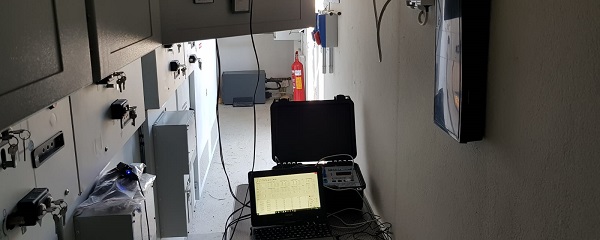

Instrumental control

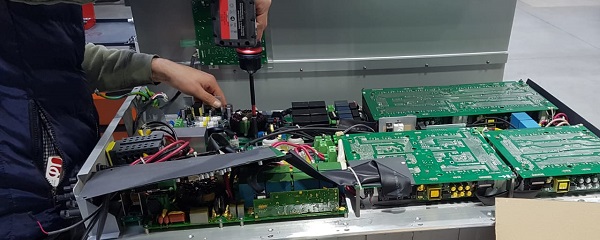

It consists in the operations aimed at the perfect conservation of the PV plant and the verification of their regular operation in the course of time. Also it consists in the operations which may also require the replacement and/or repair of mechanical, electrical parts (covered by the warranty) that should go to failure and thus be inefficient for the normal operation of the plant.

It provides:

- Visual inspection and cleaning of the equipment;

- Functional tests of circuit breakers;

- Measurement of ground resistance and insulation;

- Interface protection autotest;

- Differential protections test;

- Electrical continuity test;

- Check the power produced.

Thermography

It is very important in order to detect small electrical or structural faults of PV modules which the phenomenon of hot-spot leading the photovoltaic module to an early and fast aging. Switchboards too are checked in order to detect undersized components or wiring errors. Consider these checks also as a fire prevention.

Modules dry

Dust, soot and pollen can reduce the productive capacity of photovoltaic panels up to 30% and may even shorten the duration of the entire PV plant life cycle. Unfortunately the rain and the wind are not powerful enough to effectively clean the panels, which require regular maintenance to consistently produce a high energy level.

Our aerial platform and our equipment allow us to work anywhere and up to 20 meters high: farms, commercial buildings, factories or homes.

We remove all traces of dirt from the modules through the combined action of pressure washer, rotary brushes and degreasing detergent. The dirt is removed from the panels thanks to the detergent, the water jet coming from the pressure washer and the mechanical action of the bristles, that are made of nylon and do not scratch the surface of the module. The brushes operate at low pressure, eliminating all risks of damage to the panel.

A photovoltaic PV plant located in a favorable position, should be washed at least once a year.